Yongte WPC pelletizing machine for compounding wood and polymer is specially designed for making WPC granules from 25-30% recycled PP/PE plastic mixing with 70% wood powder, it has advantages of high output, low power consumption, automatic, easy maintainence

Wood plastic composite WPC pelletizing equipment machine uses high-tech means to efficiently process waste wood, sawdust and other organic materials into a new, high value-added material - wood plastic pellets. This pellet not only has the natural texture of wood, but also has the durability and processability of plastic. More importantly, its production process is completely green and environmentally friendly, and does not produce any harmful substances.

|

Model |

SH75 |

|

Extruder |

Parallel double screw extruder |

|

Capacity |

400-500 kg/h |

|

Main mlotor power |

90 kw |

|

screw diameter |

75mm |

|

Inverter control |

ABB brand |

|

PLC control |

Siemens brand |

|

Temperature controller |

Omron brand |

|

Material |

Wood and Plastic composite |

|

Wood percentage |

70% |

|

Plastic type |

PP/PE plastic |

Yongte high effective WPC pelletizing machine including feeding system, parallel double screw extrusion system, hot pelletizing system, blowing cooling system and material storage system

High quality driving system of Yongte WPC pelletizing machine equip with high effective motor and stronge gearbox system

automatic feeding system of Yongte WPC pelletizing machine: screw feeder and vacuum feeder are optional

Parallel double screw extrusion system of Yongte WPC pelletizing machine: high effective extrusion system with output of 600-800kg/hour.

it can work for compounding 25-30% recycled PP PE plastic with 70% wood powder

Hot pelletizing system: visionable hot pelletizing system with high output crushing equipment

Blowing cooling system: three stages blowing cooling

material storage system: all the convey pipes and storage bins are made by 304 stainless steel

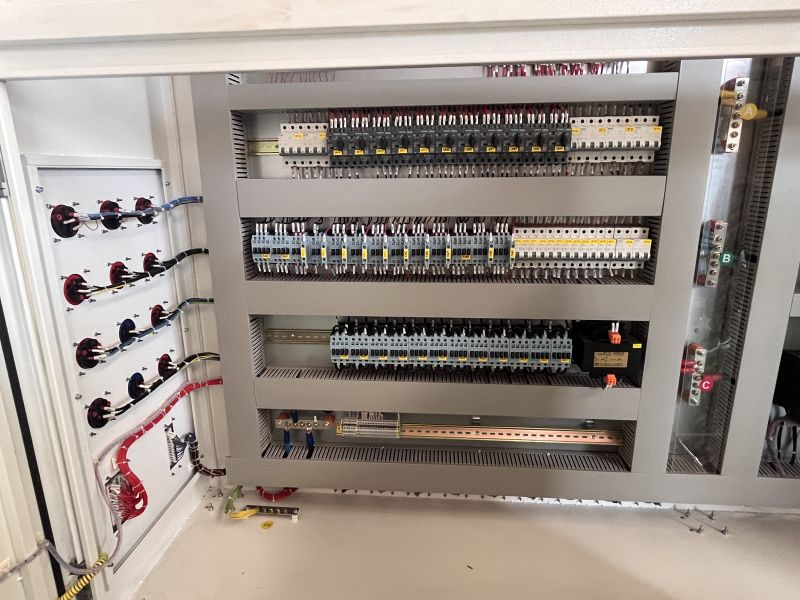

Electricity control system for Yongte WPC pelletizing machine: ABB inverter , Siemens contractor, Omron temperature controller

WPC granules made by Yongte WPC pelletizing machine: good plastization effect, uniform quality, high output

1. High efficient: Wood pelletizing equipment adopts advanced processing technology, which can quickly process wood into particles and improve production efficiency.

2. Energy saving: The equipment adopts energy-saving design to reduce energy consumption and production costs.

3. Environmental protection: During the production process, wood granulation equipment effectively reduces dust, noise and other pollution, and meets environmental protection requirements.

4. Good service: Provide professional pre-sales, sales, and after-sales services to solve user problems during use.

5. Good quality: The equipment is manufactured using high-quality materials and processes to ensure product quality and durability.

According to the characteristics of wood granulation equipment, we provide the following after-sales service and support:

1. Equipment installation and debugging: Provide users with equipment installation and debugging services free of charge.

2. Technical training: Provide equipment operation and maintenance training to ensure that users are proficient in using the equipment.

3. Regular inspections: Regular inspections of user equipment are carried out to ensure normal operation of the equipment, and potential problems are discovered and solved in a timely manner.

4. Maintenance and replacement: Provide equipment maintenance and parts replacement services to ensure long-term stable operation of the equipment.

5. Customer feedback: Collect user feedback, continue to optimize products and services, and meet user needs.

Wood plastic composite WPC pelletizing extrusion equipment has great application potential. First of all, in the construction field, we can use wood-plastic particles to make environmentally friendly building materials, such as wood-plastic doors, windows, floors, etc. These products not only have beautiful appearance, but also have excellent performance, fully complying with the concept of modern green building. Secondly, in the field of packaging, wood-plastic particles can also be processed into various environmentally friendly packaging materials, such as wood-plastic pallets, wood-plastic boxes, etc. These products are not only highly reusable, but also can effectively reduce packaging costs and improve the competitiveness of enterprises.